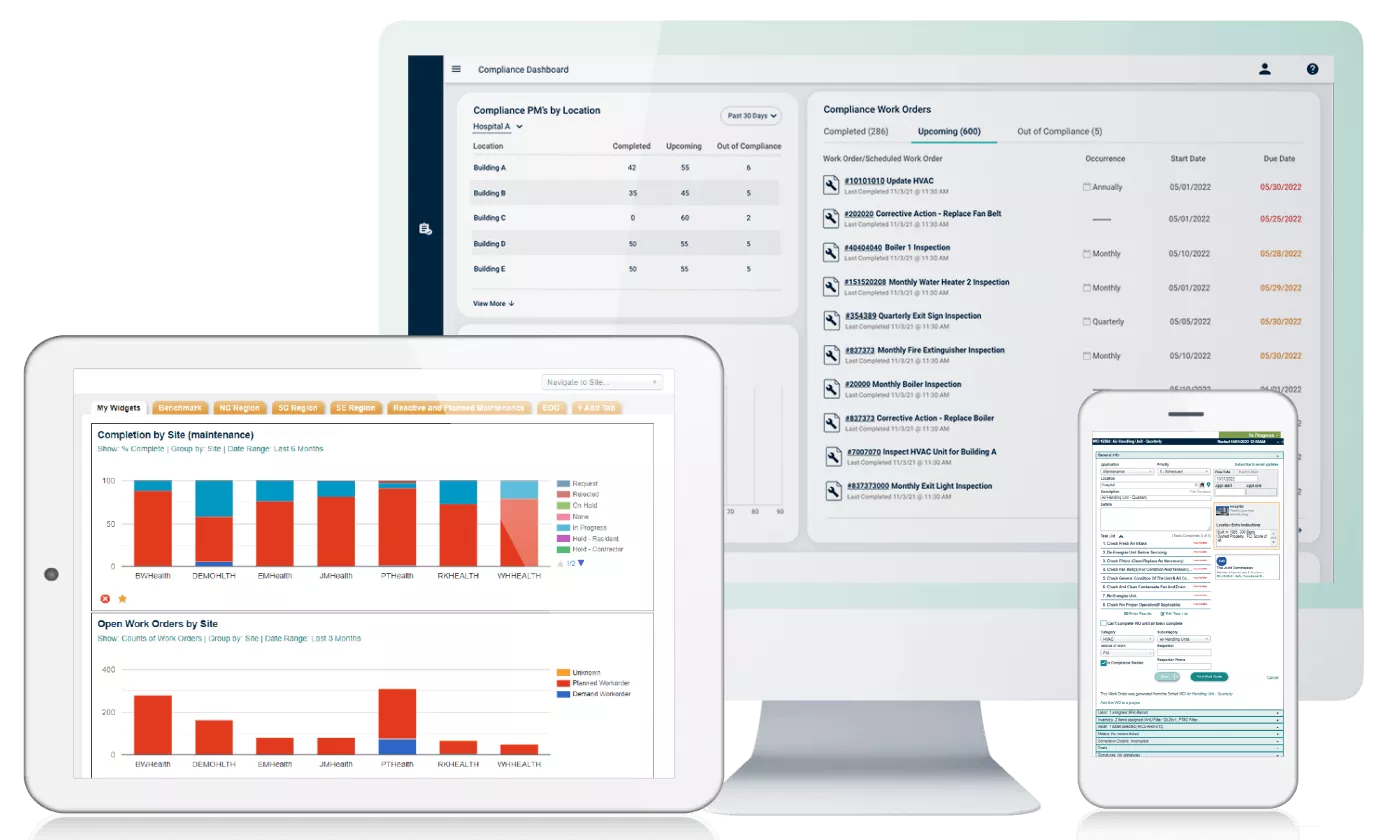

Maximize uptime with enterprise asset management

Labor and data-optimize maintenance schedules

Supercharge team with reporting & analytics information

Optimize Inventory management with real time data

“Can’t Live Without It”: Why Rinnai America Relies on Asset Essentials for Everything They Do

Rinnai America Corporation

Automation is the key to revitalize Fabricated Metal Industry

The fabricated metal industry, pivotal in supplying essential components to various sectors including construction, automotive, and aerospace, faces unique challenges such as cost pressures, competitive global markets, and the need for operational efficiency. CMMS (Computerized Maintenance Management System) and automation emerge as crucial technologies to address these challenges, revitalizing the industry.

By embracing CMMS and automation, the fabricated metal industry not only navigates its current challenges but also sets the stage for future innovation and sustainability. These technologies enable manufacturers to optimize their production lines, ensuring that equipment is maintained at peak performance and that any potential issues are addressed before they escalate into significant problems. Automation enhances precision in manufacturing processes, reducing errors and inconsistencies in the production of metal components. This shift towards data-driven management and automated operations allows companies to better predict maintenance needs, streamline their supply chains, and respond more agilely to changes in demand. As a result, businesses can achieve greater operational efficiency, reduce waste, and improve their environmental footprint, all of which are critical for staying competitive in today’s fast-paced market.

CMMS software automates the scheduling of preventive maintenance, ensuring machinery and equipment are always in optimal condition. This reduces downtime and increases production efficiency, allowing fabricated metal companies to meet tight deadlines and maintain high-quality standards.

By automating maintenance processes, CMMS helps identify and address issues before they lead to costly breakdowns. This proactive approach minimizes emergency repairs and extends the lifespan of equipment, significantly reducing operational costs.

CMMS solutions collect and analyze data on equipment performance, maintenance costs, and workflow efficiencies. This wealth of data enables managers to make informed decisions about production processes, maintenance schedules, and investments in new equipment or technologies, driving continuous improvement.

Automation in the fabricated metal industry also extends to quality control processes. Advanced sensing and measurement technologies ensure that products meet stringent quality standards, reducing waste and rework.

CMMS software helps companies adhere to regulatory compliance by keeping detailed records of maintenance activities, safety checks, and environmental controls. Automation technologies can also enhance worker safety by taking over dangerous tasks and reducing human exposure to hazardous conditions.

As demand fluctuates, CMMS and automation provide the agility fabricated metal companies need to scale their operations up or down without sacrificing efficiency or product quality. This flexibility is critical in responding to market changes and seizing new opportunities.

Supercharge asset management with Brightly’s Solutions

Establish asset hierarchies, track maintenance history on assets and prioritize planned work. Generate work orders and submit work request via online portal. Develop PM schedule and track inspections of the assets.

Our world-class strategic asset management, asset health, and capital planning solution provides strategic insight into facilities, assets, and resources that help determine where to focus limited funding.

Optimize resources and save time by removing the need to inspect assets physically with real-time asset conditions through sensor data. Operational parameters like temperature, pressure, and humidity are reported in real-time by Smart Assets sensor devices connected to the assets.

Ready to see how Brightly can simplify your asset management?

Or want to ask a question? Contact Us

FAQ

How does automation improve the quality of fabricated metal products?

Automation ensures precision and consistency in production processes, significantly elevating the quality of fabricated metal products. CMMS and asset management software handle complex manufacturing tasks with unparalleled accuracy. This not only eliminates human error but also allows for the consistent production of components with tight tolerances, directly impacting the overall reliability and performance of the finished metal products

Can CMMS and automation help in reducing the environmental impact of metal fabrication?

Yes! Brightly's CMMS solutions optimize resource use and energy consumption, support waste reduction, and facilitate sustainable practices in metal fabrication. By optimizing the scheduling of preventive maintenance, Brightly's CMMS and automation contribute to significant reductions in energy use and resource waste, aligning with environmental sustainability goals. They enable precise control over manufacturing processes, minimizing excess material usage and energy consumption, which in turn reduces the environmental footprint of metal fabrication operations

Want to uplevel your maintenance and operations?

Let us show you how our industry-leading CMMS can help!