Flexible and modular manufacturing to react to trends

Better decisions with centralized maintenance knowledge base

Meet Consumer sustainability expectations

Keep track of Regulatory changes

“It’s amazing to see pictures of what’s actually happening on that equipment. We can see what we’re loading and, in some cases, overloading. All the additional data we’re gathering allows us to paint a picture or diagnose a problem.””

Glenn Munshaw

Vice President of Operations, Chroma Color

Optimize maintenance, enhance safety, reduce costs.

Asset management seeks to deliver a measurable return on investment (ROI) for chemical manufacturers across their portfolio of assets, encompassing plants, machinery, pumps, extractors, and chemical tanks. Achieving a profitable ROI necessitates ensuring that these assets are not only operational but also performing at peak efficiency continuously.

CMMS and asset management software significantly cut operational costs in chemical manufacturing by streamlining maintenance tasks and improving equipment reliability. These solutions enable preventive maintenance, reducing downtime and emergency repairs, while also optimizing inventory levels to avoid excess costs. Moreover, they enhance energy efficiency and provide valuable insights for cost-saving decisions, ensuring a more economical and competitive operation.

Brightly's solutions offer specialized features for managing the storage, use, and disposal of hazardous materials, a critical concern in the chemical industry. By tracking the lifecycle of these materials from receipt to disposal, the software ensures proper handling, storage conditions, and timely disposal in compliance with environmental regulations.

For chemical manufacturers, maintaining continuous, efficient production processes is essential. Brightly's CMMS enhances production efficiency by minimizing unplanned equipment downtime through preventive and predictive maintenance. The system's ability to analyze equipment data and predict failures before they happen allows for maintenance to be performed without interrupting production schedules.

Inventory management of chemicals and replacement parts can be complex due to the perishable nature of some chemicals and the criticality of certain parts. Brightly's asset management software simplifies this task by providing real-time visibility into inventory levels, automating reorder processes based on predictive usage patterns, and ensuring that critical spare parts and chemicals are always available when needed.

In the chemical industry, where safety and regulatory compliance are paramount, Brightly's CMMS and asset management software stand out by ensuring that all equipment is maintained according to the highest safety standards and regulatory requirements. The system facilitates the scheduling of regular safety inspections and maintenance tasks, automatically documenting all actions taken.

Brightly's CMMS and asset management software help chemical companies achieve their environmental sustainability goals by optimizing energy use, reducing waste, and ensuring efficient use of resources. The system's monitoring and reporting capabilities allow for the detailed tracking of energy consumption and waste generation, identifying opportunities for improvement.

In the highly regulated chemical industry, maintaining comprehensive and accurate documentation for regulatory reporting is crucial. Brightly's CMMS and asset management software simplify this aspect by automating the collection and storage of essential data related to equipment maintenance, safety inspections, and environmental compliance activities.

Supercharge asset management with Brightly’s Solutions

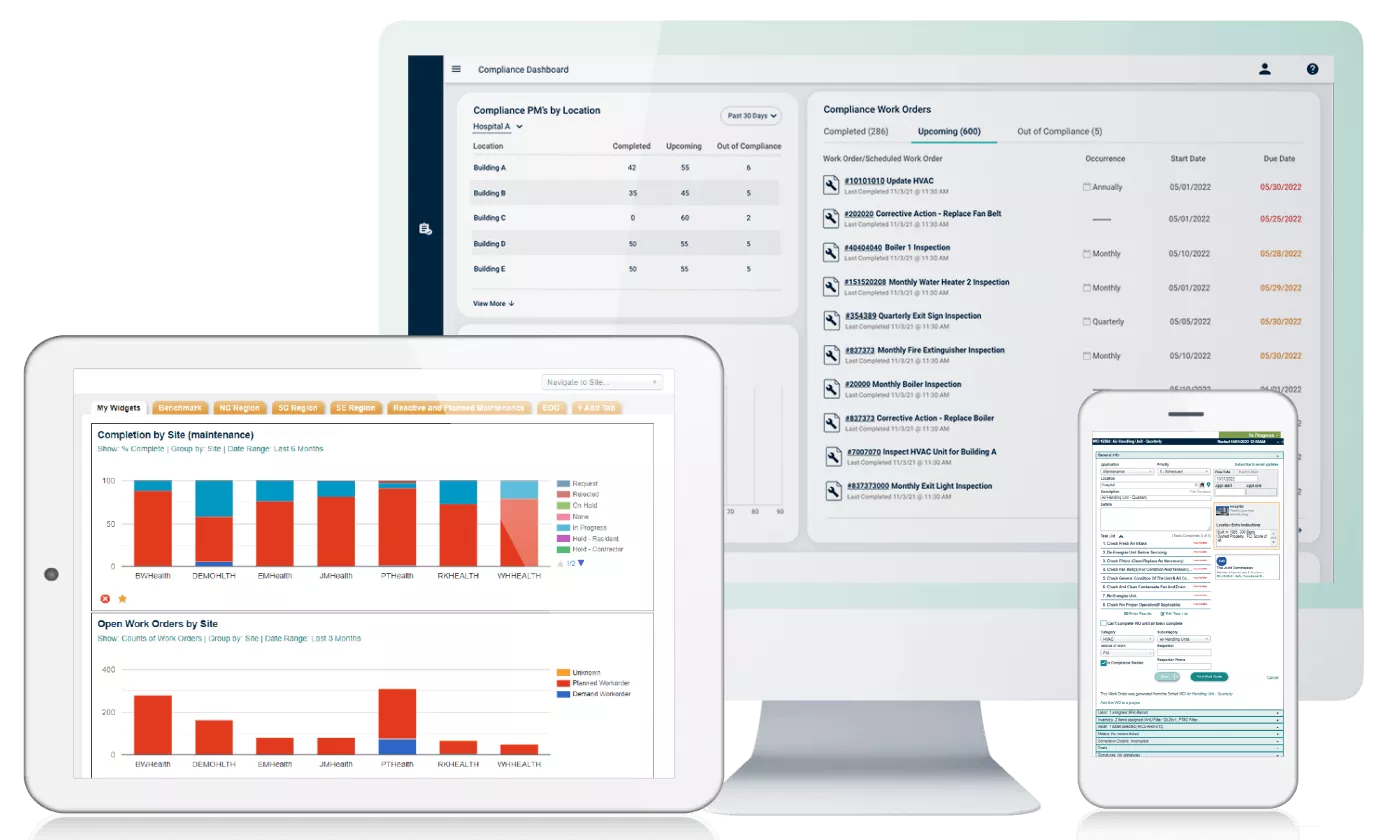

Establish asset hierarchies, track maintenance history on assets and prioritize planned work. Generate work orders and submit work request via online portal. Develop PM schedule and track inspections of the assets.

Our world-class strategic asset management, asset health, and capital planning solution provides strategic insight into facilities, assets, and resources that help determine where to focus limited funding.

Optimize resources and save time by removing the need to inspect assets physically with real-time asset conditions through sensor data. Operational parameters like temperature, pressure, and humidity are reported in real-time by Smart Assets sensor devices connected to the assets.

Ready to see how Brightly can simplify your asset management?

Or want to ask a question? Contact Us

FAQ

What Is Chemical Asset Management Software?

Chemical Asset Management Software is a specialized tool designed for tracking, managing, and analyzing data related to the assets of a chemical manufacturing plant. This includes equipment, infrastructure, materials, and personnel. The software aims to create a comprehensive repository of asset information, facilitating improved decision-making regarding the procurement, usage, maintenance, and disposition of chemical assets.

Do Chemical Manufacturers Need Software?

To stay competitive and boost the efficiency of expansive operations, chemical manufacturers stand to gain significantly from integrating software solutions. These include Asset Management Software, CMMS (Computerized Maintenance Management System), EAM (Enterprise Asset Management), and ERP (Enterprise Resource Planning) software, each offering unique advantages to streamline and optimize various aspects of their operations.

Want to uplevel your maintenance and operations?

Let us show you how our industry-leading CMMS can help!