Predictive Maintenance: Definition, FAQs, Solutions & More

What is predictive maintenance? This question has puzzled many business professionals for years, but the answer is actually quite simple - and may allow you to “see the future” as it relates to the asset management of your business.

Predictive maintenance is a technique that uses data analytics and machine learning to identify potential equipment failures before they happen.

By predicting failures, businesses can schedule repairs or replacements ahead of time, preventing system downtime and ensuring that equipment is always up and running.

But what are the benefits of predictive maintenance? And how can your business implement it? Read on for answers to these questions and more.

What is predictive maintenance?

Let’s take a closer look at what exactly predictive maintenance is so that you can decide whether implementing predictive maintenance technology is right for your business.

Definition

Predictive maintenance (PdM) is a branch of data science that uses historical data and machine learning algorithms to predict when equipment or systems are likely to fail. By scheduling maintenance before problems arise, organizations can avoid costly downtime and improve the reliability of their operations. Predictive maintenance also has the potential to improve safety by identifying hazards before they cause accidents.

Asset Essentials™ offers a comprehensive Maintenance & Operations solution that helps organizations streamline their maintenance processes and prevent equipment failures. Brightly’s predictive maintenance tool uses machine learning to identify patterns in past data and generate predictions about future equipment failures. This allows our customers to address maintenance issues before they become a problem, improving the reliability of their operations and preventing costly downtime.

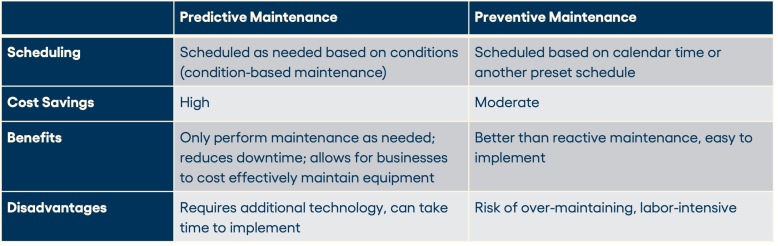

Predictive maintenance vs. preventive Maintenance

Predictive maintenance and preventive maintenance are two very different approaches to keeping machinery and equipment running smoothly.

Preventive maintenance is a scheduled approach where components and other materials are replaced and maintained regularly, whether they need it or not. Preventive maintenance is based on a schedule, with technicians performing regular inspections and repairs regardless of whether there are any issues with the equipment.

Predictive maintenance, on the other hand, uses data and analytics to determine when a component is likely to fail. As a result, organizations can target their maintenance efforts more effectively, saving time and money. In addition, predictive maintenance can help to identify potential problems before they cause downtime.

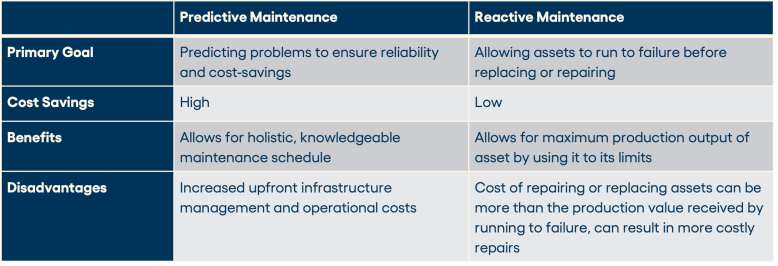

Predictive maintenance vs. reactive maintenance

The key difference between predictive and reactive maintenance is that predictive maintenance is proactive while reactive maintenance is, as the name implies, purely reactive.

Predictive maintenance is performed before a problem occurs, while reactive maintenance is only performed after a problem has already occurred. As a result, predictive maintenance can help to reduce the operational costs associated with unplanned reactive maintenance.

Predictive maintenance allows a maintenance manager to avoid the cost of downtime, as well as the cost of emergency repairs. In addition, shifting to a predictive maintenance schedule can help to improve safety by preventing accidents before they happen.

Types of predictive maintenance

There are many different types of predictive maintenance that will allow you to monitor the condition of assets, each with its own advantages and disadvantages. Let’s take a closer look.

Vibration analysis

Vibration analysis is the process of measuring and analyzing vibrations to diagnose problems in machinery. It is a non-destructive testing technique that can be used to detect defects in everything from aircraft engines to bridges.

Vibration analysis has several advantages over other methods of testing, such as being able to test parts while they are still installed and in use. This can help to avoid the cost and downtime associated with removing and replacing components.

Vibration analysis is also relatively low cost, especially when compared to the cost of repairing or replacing damaged machinery.

Oil analysis

Oil analysis is the process of testing used lubricating oil to determine its condition and suitability for continued use. The advantages of oil analysis include the ability to extend oil drain intervals, reducing both the cost and environmental impact of used oil disposal.

Oil analysis can also be used to troubleshoot equipment problems, by identifying contaminants that may be causing wear or other issues. While there is a cost associated with sending oil samples out for testing, this is typically outweighed by the savings achieved through extended drain intervals.

Acoustic analysis

Acoustic analysis is the study of sound and vibration. It can be used to identify the source of noise, measure the sound level of a noise, or determine the frequency of vibration. Acoustic analysis is often used in industrial settings to monitor machinery for potential problems. It can also be used to diagnose problems with building systems, such as HVAC systems.

Acoustic analysis is relatively inexpensive and can be performed quickly, making it an attractive option for troubleshooting noise and vibration issues.

How does predictive maintenance work?

Predictive maintenance (PdM) is a process that uses data to determine when equipment is likely to fail, so that repairs can be scheduled in advance. Predictive maintenance can help to improve equipment uptime and reduce the cost of repairs.

The first step in predictive maintenance is to gather data about the equipment. This data can be collected manually or through sensors. Once the data has been collected, it is analyzed to look for patterns that indicate when equipment is likely to fail. Finally, this information is used to create a schedule for maintenance and repairs. The right computerized maintenance management system (CMMS) can play a vital role in successful predictive maintenance by helping to collect, store, and analyze data.

Baseline analysis

Establishing an asset's baseline is an important first step in implementing a predictive maintenance program. This baseline is created by analyzing the asset's historical data to identify patterns of normal behavior. After all, without a control, there’s no way to identify abnormalities or to monitor the performance of assets, purely because you don’t know what “normal” looks like.

Once the baseline is established, sensors can be used to monitor the asset's current condition and flag any deviations from the norm. By catching problems early, predictive maintenance can help extend the life of an asset and avoid costly downtime.

Asset condition monitoring

One of the most important aspects of predictive maintenance is asset condition monitoring. This is typically done with the help of sensors that are placed on critical components. These sensors collect data about things like vibration, temperature, and oil levels. This data is then transmitted back to a central database for analysis. If the data indicates that an asset is in need of maintenance, the appropriate protocol will be triggered.

Implementing an Internet of Things (IoT) solution for predictive maintenance can have a significant impact on an organization’s bottom line. It allows for automated asset condition monitoring by using sensors and machine-to-machine communication. When an asset is in need of maintenance, the sensors will trigger the assigned predictive maintenance protocol automatically.

CMMS-Generated work orders

One way that predictive maintenance can be carried out is through the use of CMMS-compatible sensors. These sensors can monitor the performance of an asset and identify when it falls outside of its established parameters.

When this happens, the CMMS system can generate a work order specifically tailored to the needs of the asset. This helps to ensure that issues are addressed before they cause major problems.

To successfully carry out predictive maintenance, it is essential to have a CMMS solution that is compatible with the sensors being used. Brightly offers a variety of asset management tools that are designed to work with a wide range of sensors.

Benefits of predictive maintenance

By using data to identify potential problems before they occur, predictive maintenance helps to minimize unplanned downtime, reduce the need for emergency repairs, and extend the lifespan of the equipment. Perhaps most importantly, predictive maintenance can help to improve safety by preventing accidents and injuries.

A CMMS is essential for achieving the full potential of predictive maintenance, as it provides a centralized platform for storing data and generating reports.

Reduce maintenance costs

One of the most obvious ways predictive maintenance can impact your business's ROI is by reducing the total time and maintenance costs associated with maintaining equipment. Rather than waiting for something to break down before fixing it, predictive maintenance catches potential problems early, often before they result in downtime. This proactive approach can save your business a lot of money in the long run.

Increase productivity

Predictive maintenance can also create automated workflows that lead to increased productivity. For example, if a particular piece of equipment needs to be regularly calibrated, a predictive maintenance planning program can create a schedule for when that calibration needs to happen. This takes the guesswork out of maintaining equipment and allows your team to focus on other tasks.

Improve safety

In addition to saving money and increasing productivity, another key benefit of predictive maintenance is improved safety. By reducing unexpected equipment failures, predictive maintenance helps create a safer work environment for everyone involved. This is especially important in industries where employees are already working with dangerous machinery on a daily basis.

Make smarter decisions

The combination of predictive maintenance and utilizing a CMMS also allows for accurate capital forecasting and better budget decision-making. With this information at your fingertips, you'll be able to make smarter decisions about what repairs or replacements need to be made and when. This helps you avoid wasting money on unnecessary repairs while still ensuring that your equipment is well-maintained.

Boost ROI

Predictive maintenance can seem like a daunting and expensive undertaking, but the reality is that it can be a highly effective way to boost ROI.

By making use of data collected by sensors and other devices, predictive maintenance allows businesses to plan and execute maintenance tasks before problems arise. This not only prevents downtime but can also significantly reduce repair costs. In addition, predictive maintenance can help businesses to optimize their production schedules, leading to increased efficiency and productivity.

Predictive maintenance best practices

Predictive maintenance requires both a sound data collection strategy and robust analytical tools to be effective. Here are a few best practices to keep in mind when creating and implementing predictive maintenance:

Start small

When first starting out with predictive maintenance, it’s best to focus on a few critical assets. This will allow you to gauge performance and identify any changes that need to be made to your predictive maintenance program. Once you’ve perfected your process for these assets, you can then roll it out to other parts of your operation.

Optimize as needed

Organizations should use asset performance data collected over time to optimize conditional baselines and generate better predictions. As your predictive maintenance

program matures, you’ll want to continuously review and update your approach so that you can get the most accurate results possible.

Leverage IoT

IoT creates an automated workflow that can help streamline predictive maintenance

processes. By connecting sensors to equipment, you can remotely monitor assets and receive real-time alerts when something isn’t operating as it should. This enables you to take a corrective maintenance action before an issue causes downtime.

Streamline predictive maintenance processes with the right CMMS

A computerized maintenance management system (CMMS) like Brightly can help streamline your predictive maintenance program by automating key tasks such as work order creation and scheduling. With Brightly, all your predictive maintenance data is stored in one central location, making it easy for you to track assets, schedule repairs, and measure results over time.

Implement predictive maintenance with Brightly’s CMMS solutions

Predictive maintenance is a type of maintenance that uses data and analytics to identify potential equipment failures before they happen. By catching problems early, predictive maintenance can help to avoid unplanned downtime and save businesses money.

Brightly's computerized maintenance management system (CMMS) solutions can help businesses to implement a successful predictive maintenance program.

Our software makes it easy to track equipment data and identify trends that could indicate an upcoming failure. We also offer expert support and guidance to help businesses get the most out of their predictive maintenance program. As a result, working with Brightly is the best way to ensure a successful predictive maintenance implementation.

We have several solutions available in select geographies, but here are a couple of products to keep in mind as you begin to plan:

Asset Essentials

Asset Essentials is a world-class system that can be used for all kinds of assets and facilities, allowing you to streamline tasks and word orders so that you can both plan and schedule preventive maintenance with the most up to date information.

Using Asset Essentials can lead to a significant increase in ROI. Find out more and request a free custom demo today.

Confirm

Confirm is a smart and cost-effective solution to help you manage your public infrastructure assets. You’ll get the insight you need to add value across your organization with a seamless solution - and with end-to-end capabilities, it’s easier than ever to get started.

Request a free custom demo to find out if Confirm is right for you.

So, what are you waiting for? Implementing the right predictive maintenance technology can make a huge difference when it comes to getting (and using) the real time data your business needs to stay profitable. Our team is ready to help you decide what type of software is best for your organization and maintenance and operations heros.