The Biggest Trends and Challenges for Fabricated Metal Manufacturers

The North American fabricated metal market is expected to pass $473.7 billion by 2031. Yet despite its strong trajectory and reported yearly sales of nearly $520 million, the industry faces significant challenges today, like supply chain disruptions and labor shortages.

In this blog, we’ll discuss these challenges and highlight a current trend that could offer a pathway to overcoming these hurdles and achieving more advanced growth.

Supply chain disruptions

The COVID-19 pandemic and other global events have caused continued disruptions to supply chains, affecting inbound logistics, raw materials, and outbound deliveries. In 2022, research from SYSPRO found that 82% of fabricated metal companies were experience supply chain issues, leading to decreased margins. And many are still dealing with these issues today.

One of the major contributing factors today is inflation, which has a significant impact on the overall cost and availability of raw materials. This causes increasing high lead times, making it harder for companies to consistently meet customer expectations.

In this volatile market, with increasing customer demands for higher quality and better customer experiences, manufacturers need to find new ways to be deliver, like collaborating closely with current suppliers or coming up with alternative sourcing opportunities to manage these uncertainties.

Labor shortages

The labor shortages across North America have significantly impacted the fabricated metal industry, particularly in skilled trades. This shortage, driven by the retirement of generational workers and a gap in skills among the current workforce, poses a major challenge.

To overcome these hurdles, manufacturers should focus on attracting new, high-level talent by offering better pay and benefits or providing more training and growth opportunities for current employees.

Adopting new innovative technology solutions like a CMMS can also help prioritize labor resource planning and accelerate maintenance workflows. A CMMS can serve as a single source of truth for all processes, procedures, compliance requirements, and asset information which can reduce the impact of one or more employees leaving your organization.

Industry 4.0

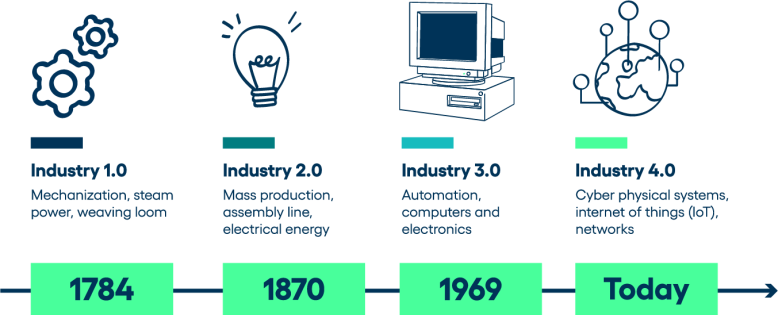

Industry 4.0 (otherwise known as the 4th industrial revolution) continues to be a game-changer for the fabricated metal industry, encompassing a range of innovations and new technologies designed to increase efficiency and productivity.

The trend, which officially started back in the 2010 range, includes many technologies to enhance how manufacturers create, distribute and support products around the globe. This includes things such as the Internet of Things (IoT), 3D printing (a.k.a. “additive manufacturing”), Artificial Intelligence (AI) and many others. This technology has led much of the industrial world into a “digital transformation."

Embracing these innovations offers a real opportunity to enhance productivity, improve quality, reduce costs, and enable end-to-end traceability and customization. By adopting these technologies, manufacturers can more rapidly adapt to evolving customer needs and remain highly competitive in a dynamic market.

Moving forward

The future of the fabricated metal industry in North America looks promising, with the potential for significant growth driven by technological advancements. By embracing new ideas in Industry 4.0, addressing supply chain disruptions, and tackling labor shortages through innovative workforce strategies, the industry can navigate current challenges and continue to thrive in the coming years.

Looking for other low-investment, high-impact tools to enhance your daily operations? Check out this short article on the 5s Methodology for Lean Manufacturing.