What is a CMMS?

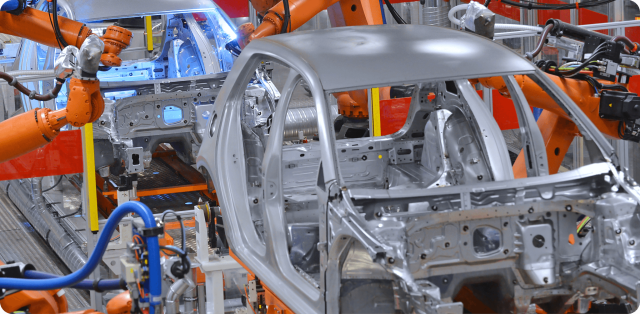

A computerized maintenance management system (CMMS) is a software solution designed to accelerate maintenance processes, improve operational productivity, reduce costs tied to unplanned downtime, and extend the lifespans of your physical assets, facilities, and infrastructure.

Organizations can use a CMMS to organize their asset data into a centralized registry, automate work order assignments and tracking, and optimize maintenance scheduling to increase efficiency and eliminate time waste.

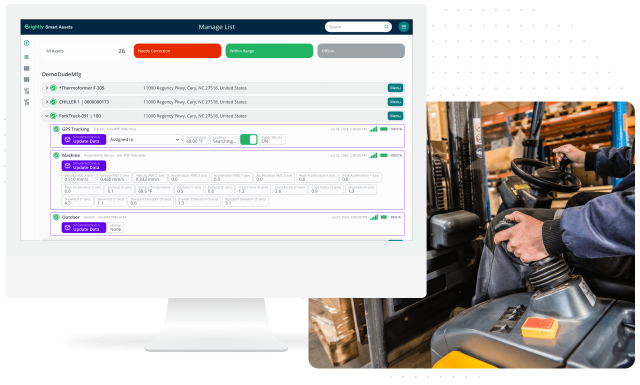

Brightly Software is a leader in asset lifecycle management and operations with world-class CMMS solutions for maintenance and facilities leaders in education, manufacturing, government, healthcare, senior living, and commercial real estate.

Why is a CMMS important?

Without a CMMS, organizations often struggle organizing spreadsheets or using outdated pen-and-paper methods to keep track of repairs and replacement needs. This frequently leads to a cycle of reactive maintenance, inefficiencies in time and resource usage, and unexpected downtime.

Disorganized workflows and lack of data-driven decision-making lead to higher expenses and reduced asset reliability. A CMMS can help address these challenges by providing a structured system for tracking assets, scheduling maintenance proactively to prevent unplanned failures, and analyzing performance data to improve efficiency and cost control.

What are the core features of a CMMS?

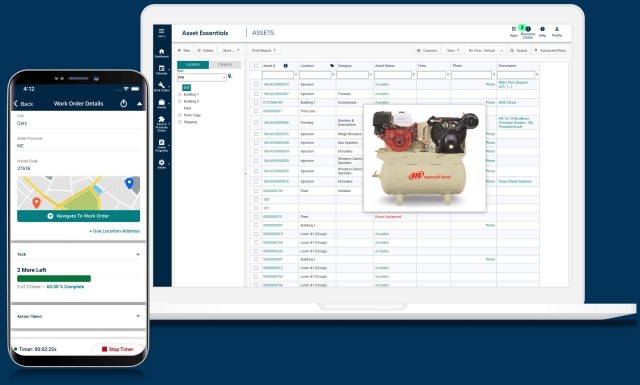

Asset registry and management

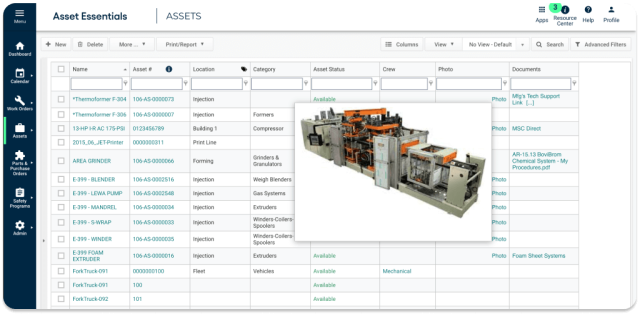

A modern CMMS should allow organizations to keep track of their assets, including locations, sub-locations, key details like make, model, warranty information, and repair history to identify trends in maintenance needs that could signal a need for replacement.

Brightly’s CMMS solutions centralize maintenance data, providing real-time insights and facilitating more effective communication among maintenance teams.

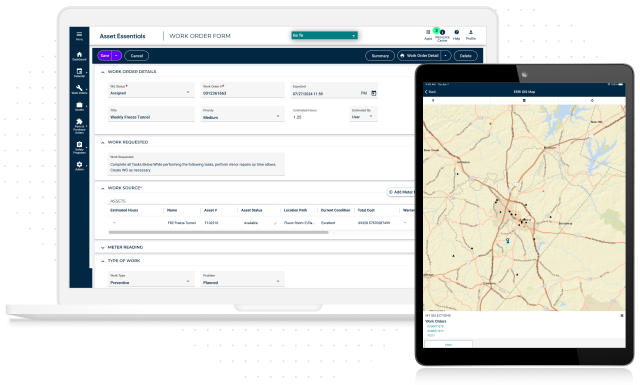

Work order and resource management

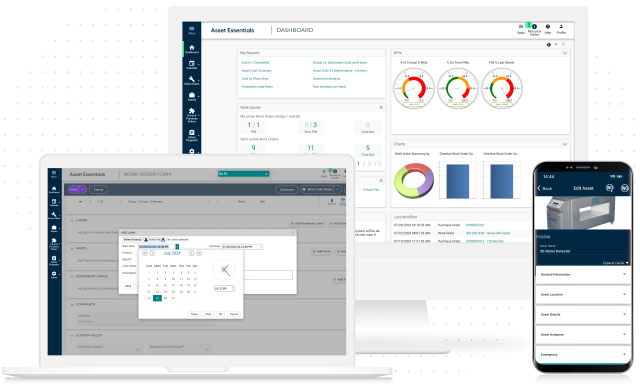

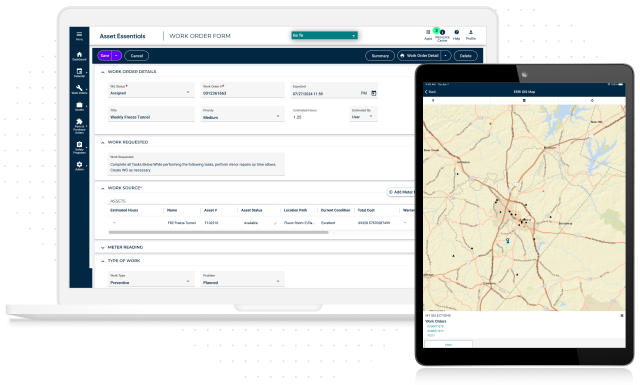

CMMS solutions allow users to create, track, and manage work orders for maintenance tasks. This helps simplify and accelerate the process by automatically create a work order, assigning it directly to the necessary technicians, and tracking its progress through to completion.

With mobile access and real-time updates, technicians can also receive and complete work orders in the field, improving responsiveness and reducing delays. Prioritization and scheduling features for work orders also ensure critical maintenance tasks are addressed promptly and don’t go unnoticed.

Proactive maintenance

Preventive maintenance is a scheduled maintenance plan performed on assets or equipment to improve performance, extend asset life and prevent breakdowns. An example of might be a manufacturing facility that has a schedule to change the oil and filters on their production equipment every 3 months or 500 operating hours.

Predictive maintenance is a more advanced approach that uses data-driven insights to predict when equipment or assets will require maintenance. For instance, a wind turbine operator may use vibration analysis and temperature monitoring to detect early signs of wear, allowing them to schedule maintenance before a catastrophic failure occurs.

A CMMS is vital for both preventive and predictive maintenance as it empowers you to automate the scheduling of proactive maintenance tasks, track asset performance data, and analyze your asset data to inform maintenance decisions.

Inventory and materials management

Effective spare parts tracking ensures organizations avoid stockouts and manage procurement more efficiently. Brightly’s CMMS provides real-time visibility into spare parts and inventory levels, tracks consumption patterns, and triggers reordering to prevent stockouts. It also minimizes excess inventory, reduces costs, and ensures critical parts are always available.

Reporting and analytics

Real-time dashboards, KPIs, and customizable reports provide organizations with insights into maintenance operations are all features of a strong, modern CMMS. By leveraging data-driven decision-making, maintenance teams can optimize their workflows, prioritize needs, improve long-term asset performance, and reduce costs.

CMMS offer many valuable benefits for maintenance and operations leaders. Here are a few of the most useful:

A CMMS enhances task prioritization, reduces delays, and streamlines workflows, ensuring that maintenance teams can work smarter and more efficiently. By automating work orders, tracking asset conditions, and enabling mobile access for technicians, it minimizes downtime and keeps things running smoothly. With better resource allocation and scheduling, teams can focus on preventive maintenance instead of just reacting to emergencies.

By enabling proactive maintenance and creating more efficient workflows, a CMMS can help extend asset lifespans and reduce costs associated with emergency repairs and unplanned downtime. This can also improve inventory management by eliminating unnecessary purchases and reducing wasted stock. Predictive maintenance capabilities can further lower expenses by identifying potential failures early, avoiding any costly breakdowns.

A CMMS with centralized data fosters better collaboration among teams by giving all necessary departments real-time updates, notifications, and alerts for maintenance tasks. Technicians, managers, and other key stakeholders can easily access maintenance histories, asset data, and work order statuses all in one place, reducing miscommunication and preventing delays. This transparency not only ensures maintenance teams stay aligned on priorities, it also improves accountability for everyone involved.

With a CMMS, organizations can track compliance requirements for industry standards, like ISO or OSHA, and ensure that all safety documentation and audit records are maintained. A CMMS also helps schedule safety inspections, manage permits, and generate compliance reports, reducing the risk of regulatory fines for noncompliance. By keeping detailed maintenance logs, organizations can ensure – and prove – adherence to safety protocols and create a safer work environment for their teams.

Choosing the right CMMS depends on more than just picking the least expensive option. With over 400 CMMS solutions available, and more flooding the market every year, it’s important to consider factors unique to you – like organization size, budget, asset complexity, industry standards, etc. -- to ensure you choose the option that is right for you.

When choosing a CMMS, ensure it provides essential functions like asset tracking, work order management, compliance and safety tracking, and inventory control. From there, you can determine whether it supports advanced capabilities you might need, like predictive maintenance, reporting, analytics, mobile functionality, etc.

While entry-level solutions might seem cost-effective, they can become expensive as needs grow, with additional costs for added features and functionality. Choose a scalable solution that aligns closely with your long-term goals to avoid expensive system migrations.

Selecting a CMMS provider isn’t just about software – it’s about a long-term partnership. Look for a vendor with industry expertise, strong customer support, and a track record of innovation.

Your checklist for choosing the right CMMS

- Does the CMMS include work order management, asset tracking, preventive maintenance, and inventory management?

- Can the CMMS grow with your organization as your needs evolve?

- Beyond the initial price, does the CMMS require added costs for upgrades, support, and additional features?

- Is the interface user-friendly for your technicians and administrators?

- Does the CMMS provide a mobile app or cloud-based access for your remote teams?

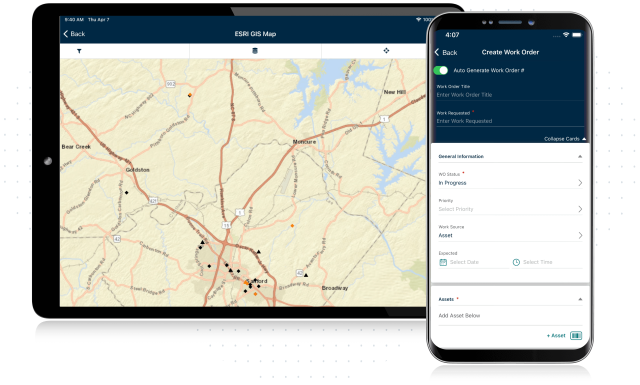

- Can the CMMS integrate with existing systems like ERP, IoT, GIS mapping, and energy management tools?

- Does the CMMS offer real-time dashboards, performance tracking, compliance reporting, etc.?

- Does the CMMS support the unique needs of your industry (e.g., compliance tracking for healthcare, energy optimization for education)?

- Can you tailor workflows, dashboards, and notifications to match your current processes?

- Is the CMMS provider established and reliable, with a strong reputation and proven customer support?

Brightly Software offers market-leading CMMS solutions designed to enhance work order management, increase maintenance efficiency, improve inventory management, and reduce operational costs. Our solutions – like Asset Essentials and TheWorxHub – provide powerful, yet intuitive interfaces that simplify work order generation by capturing only necessary asset details while automatically applying relevant compliance standards. This ensures maintenance teams can work efficiently without unnecessary administrative burden.

Brightly Asset Essentials is a world-class CMMS designed to meet the complex needs of education, manufacturing, and government leaders. Asset Essentials goes beyond basic maintenance management, offering advanced features like IoT integration, GIS mapping, and mobile accessibility. These capabilities help teams automate work orders, optimize asset lifecycles, and gain real-time insights to drive smarter decision-making. By leveraging Asset Essentials, organizations can reduce downtime, increase efficiency, and extend asset longevity through proactive maintenance strategies.

TheWorxHub is a cloud-based CMMS purpose-built for the unique needs of healthcare facilities and senior living communities. TheWorxHub simplifies facility management by streamlining maintenance workflows, ensuring compliance with industry regulations, and optimizing energy consumption. Designed to enhance resident and patient safety, it provides a centralized platform for tracking work orders, managing preventive maintenance, and integrating compliance reports – empowering facility teams to deliver high-quality service while maintaining safer, more comfortable environment for all.

Getting started with Brightly’s CMMS

Implementing a CMMS is a strategic investment in the efficiency, reliability, and longevity of your assets. Brightly’s CMMS solutions make it easy to transition from outdated processes to a modern, data-driven maintenance strategy.

Steps to get started:

- Schedule a demo: See Brightly’s CMMS in action and explore how it fits your organization’s unique needs.

- Assess your needs: Work with our experts to identify the best solution based on your industry, asset complexity, and long-term goals.

- Learn about implementation: Our award-winning team can give you an overview of the hands-on support you will receive during implementation to ensure a smooth transition, from data migration to user training, and more.

Ready to transform your maintenance strategy? Discover how Brightly’s CMMS can streamline your operations, enhance efficiency, and drive long-term success.

FAQs

What is a CMMS and how does it work?

A CMMS, or computerized maintenance management system, is software that helps organizations manage and optimize their maintenance activities. It works by centralizing maintenance data, automating work orders, creating a place to schedule preventive maintenance, tracking asset performance, and providing insights to improve operational efficiency. A CMMS enables organizations to reduce downtime, control costs, and extend the lifespan of their assets.

What industries can benefit from CMMS?

CMMS solutions are valuable across industries, including education, healthcare, senior living, manufacturing, government, commercial real estate, and more.

How does CMMS save costs?

A CMMS reduces costs by preventing unexpected equipment failures, automating work order management, optimizing labor efficiency, tracking spare parts to reduce unnecessary stock purchases, and ensuring compliance to avoid regulatory fines. Proper maintenance extends asset lifespan, reducing capital expenses.

What is the difference between CMMS and EAM?

While a CMMS focuses primarily on maintenance tasks like work order management and preventive maintenance scheduling, enterprise asset management (EAM) system covers the entire asset lifecycle, including procurement, financial planning, and capital investment. This makes a CMMS more ideal for daily maintenance operations, while EAM provides a more holistic approach to asset management.