Strategic Asset Management in Manufacturing: How to Manage Your Assets So They Don't Manage You

In manufacturing, finding ways to consistently improve or maximize overall productivity and quality is key to a company’s long-term success.

Budgetary constraints, workforce shortages, and aging equipment and facilities are daily concerns for operations and facilities leaders in manufacturing.

While finding a way to balance these various challenges seems never-ending, gathering and leveraging the data to build capital plans and budgets can make the process easier by giving you the information you need to make smarter, more strategic decisions around asset health.

Achieving this is only possible with the right systems in place. And that’s where strategic asset management (SAM) comes into play.

What is strategic asset management?

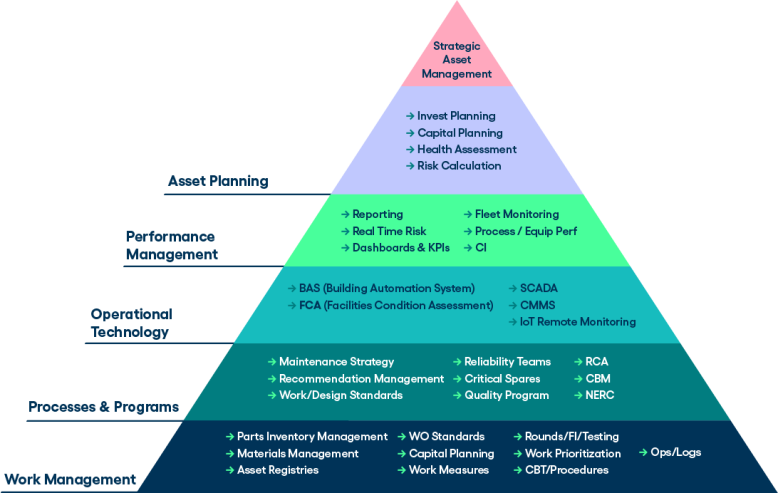

Strategic asset management is an established approach to asset management for long-term planning of maintenance and operations. It provides a framework that can be used to understand and visualize your asset management needs today or five, 10 and even 20+ years into the future.

SAM can help manufacturers understand the current condition of their assets and provide them with accurate data to identify and forecast potential outcomes around maintenance needs, capital planning, and investments.

By utilizing strategic asset management, you can prioritize long-term physical asset investments, gain a broader view of your current asset needs and determine what you will need in the coming years, so you can make decisions that align best with your company goals.

Why is strategic asset management important?

By understanding which assets are most vital to operations, manufacturers can allocate resources more effectively, ensuring that critical equipment receives the necessary attention and investment. This approach helps prevent unforeseen failures and ensures resources are allocated in the most effective way possible.

Proactive monitoring and maintaining of assets also help manufacturers avoid high costs associated with unexpected breakdowns and repairs. This not only saves money, but minimizes disruptions to production, ensuring that operations run smoothly and efficiently.

Strategic asset management provides detailed insights into asset performance that manufacturers need to develop long-term plans that align with their strategic goals. Having a forward-thinking approach ensures that investments are made wisely, leading the way to more sustainable growth and long-term success

3 benefits of strategic asset management

For manufacturers, implementing a strategic asset management solution in your operations can help you gain more from the assets you have already invested in, avoid costly mistakes, and build a culture where groups work together to achieve a common goal.

1. Keep your community and stakeholders informed

When stakeholders have access to detailed and reliable data, they can make informed decisions on when to repair or replace assets to reduce unexpected downtime. Whether it's manufacturing facilities or fleet vehicles, leveraging the right data ensures that stakeholders understand how assets are performing and their impact on the business now and in the future.

2. Support budget and funding requests

SAM solutions support budget and funding requests by providing a detailed analysis of costs associated with maintaining an existing asset base. If an organization decides to replace its fleet of vehicles, SAM software can track maintenance costs for each vehicle in its fleet over time and use this data to estimate future maintenance costs for new vehicles.

3. Reduce costs

By proactively monitoring and maintaining assets, these solutions help reduce unnecessary costs associated with equipment downtime, unexpected failures, and inefficient resource use. This not only saves money but also minimizes disruptions to operations, enhancing overall productivity.

With strategic asset management, companies can achieve a more complete understanding of their assets, which leads to better decision-making, efficient resource allocation, and long-term planning.

As manufacturing environments become increasingly competitive and resource-constrained, adopting SAM solutions is becoming essential for driving sustainable growth, optimizing productivity, and securing a successful future for your organization. If you are interested in learning more about strategic asset management and how it can benefit your organization, I'll be hosting a webinar in the coming weeks called “Master Data Planning: Manage Your Assets So They Don't Manage You” You can register to attend by using the link below.