Prolong asset lifecycle with strategic maintenance

Streamline inventory management with precision

Transparency with centralized maintenance knowledgebase

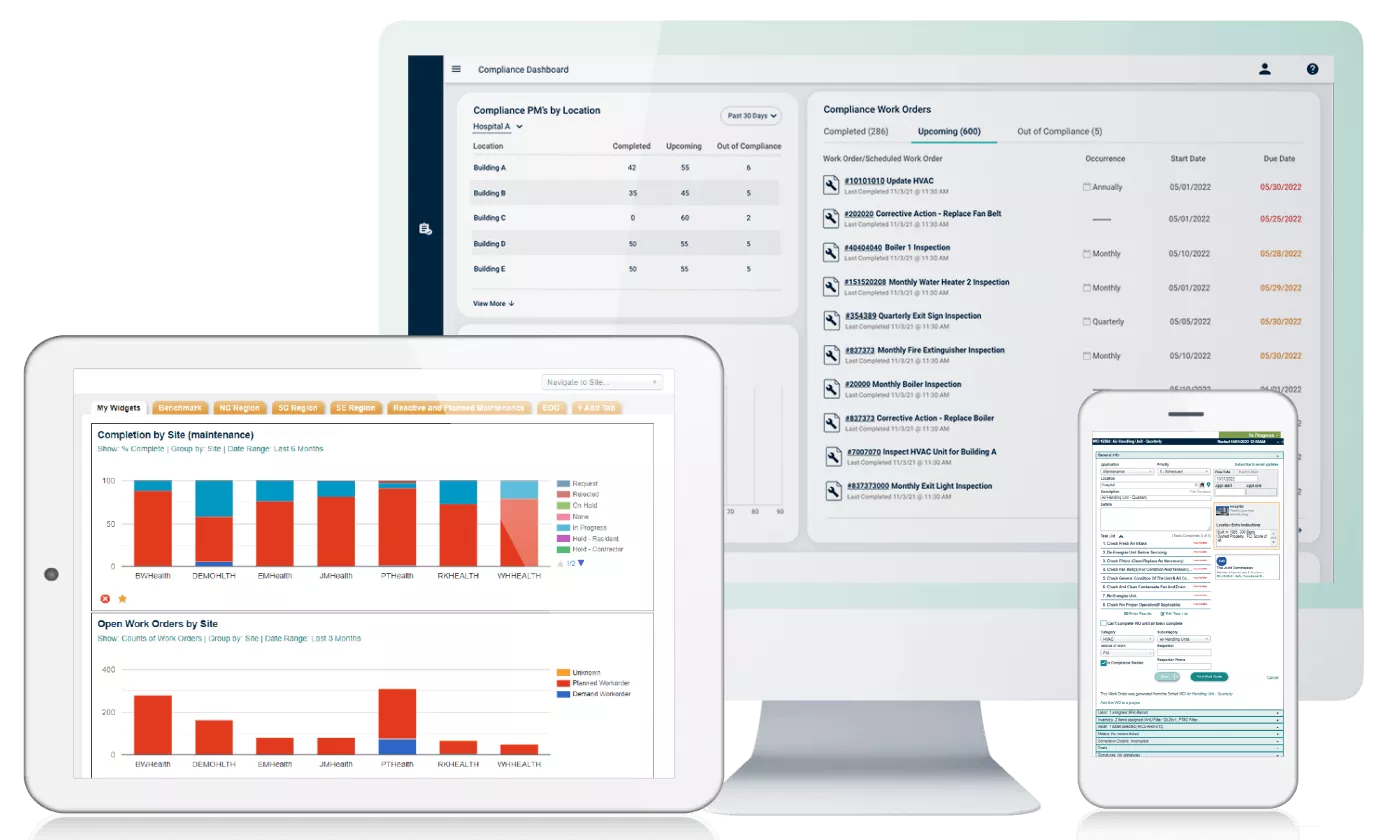

Take control of operations with data-driven insights

“Brightly has helped us better maintain our equipment by clearly demonstrating when a change in maintenance frequency is necessary and the ability to add tasking is immediate.”

Dale Stein

Plant Engineer, Pepsi Bottling Ventures

Trends & Challenges in Food & Beverage

Brightly's CMMS solutions extend the lifespan of equipment by facilitating preventive maintenance, addressing issues before they escalate into failures. This proactive approach not only diminishes the necessity for expensive repairs and replacements, thereby saving money over time, but it also guarantees continuous production by significantly reducing the incidence of unforeseen equipment breakdowns.

Brightly's CMMS aids the food and beverage industry by streamlining inventory management, ensuring that critical spare parts and supplies are always available when needed, without overstocking. Through precise tracking and automated reorder alerts for inventory levels, Brightly's system reduces the risk of production delays due to parts shortage and lowers costs associated with holding excess inventory.

In the food and beverage industry, maintaining product quality is paramount. Brightly's CMMS contributes to enhanced quality control by ensuring that all equipment and machinery are maintained in peak condition, adhering to the strictest hygiene and operational standards. Scheduled maintenance and checks, informed by the CMMS, help prevent contamination and product inconsistency, leading to a higher quality end product.

Supercharge asset management with Brightly’s Solutions

Establish asset hierarchies, track maintenance history on assets and prioritize planned work. Generate work orders and submit work request via online portal. Develop PM schedule and track inspections of the assets.

Our world-class strategic asset management, asset health, and capital planning solution provides strategic insight into facilities, assets, and resources that help determine where to focus limited funding.

Optimize resources and save time by removing the need to inspect assets physically with real-time asset conditions through sensor data. Operational parameters like temperature, pressure, and humidity are reported in real-time by Smart Assets sensor devices connected to the assets.

Ready to see how Brightly can simplify your asset management?

Or want to ask a question? Contact Us

FAQ

Why do food and beverage manufacturers need a CMMS?

A Computerized Maintenance Management System (CMMS) is crucial for food and beverage manufacturers to enhance operational efficiency, ensure regulatory compliance, and manage costs effectively. By automating maintenance schedules, optimizing resource allocation, and providing data-driven insights, CMMS enables manufacturers to maintain high-quality production standards and extend the lifespan of their equipment

Want to uplevel your maintenance and operations?

Let us show you how our industry-leading CMMS can help!