Maintain your entire distribution center from a single screen

Streamline inventory management

Track and prioritize labor resources

Reduce complexity in day-to-day operations

Distribution industry trends

Through global supply chain disruptions, rapid technological evolutions, and changing habits among buyers and sellers, wholesale distributors have had to deal with rapid and radical changes over the past couple of years.

Covid-19 was a great example, which caused major constraints in the supply chain, leading companies to begin using digital platforms to overcome these restrictions.

Some major recent highlights for the distribution industry include:

- Organizations becoming increasingly automated.

- Warehouse management software enabling next-level inventory tracking.

- The use of data & analytics tools has rapidly increased.

- Manufacturers are increasingly contacting customers directly.

- The focus on sustainability is growing to increase overall profitability.

- The trend of using wholesale ecommerce is emerging.

- AI is taking over as the distributors shift to predictive analytics.

By automating maintenance schedules, a CMMS significantly reduces equipment downtime, while its real-time management of work orders and inventory ensures optimal resource allocation. This streamlined approach to maintenance not only boosts productivity but also lowers operational costs by enhancing equipment performance, offering a comprehensive solution to maintaining high efficiency in operations.

Brightly's CMMS aids the distribution industry by streamlining inventory management, ensuring that critical spare parts and supplies are always available when needed, without overstocking. Through precise tracking and automated reorder alerts for inventory levels, Brightly's system reduces the risk of supply chain delays due to parts shortage and lowers costs associated with holding excess inventory.

Brightly’s Data & Analytics tools help generate different KPI reports to help companies forecast future outcomes and drive smarter, more data-driven decision-making.

Monitoring data across locations, shifts, assets and more allows easier central monitoring and agile decision-making. With predictive maintenance capabilities, manufacturers can also reduce the risk of unexpected breakdowns, allowing for greater flexibility in production schedules.

Supercharge Asset Management with Brightly’s Solutions

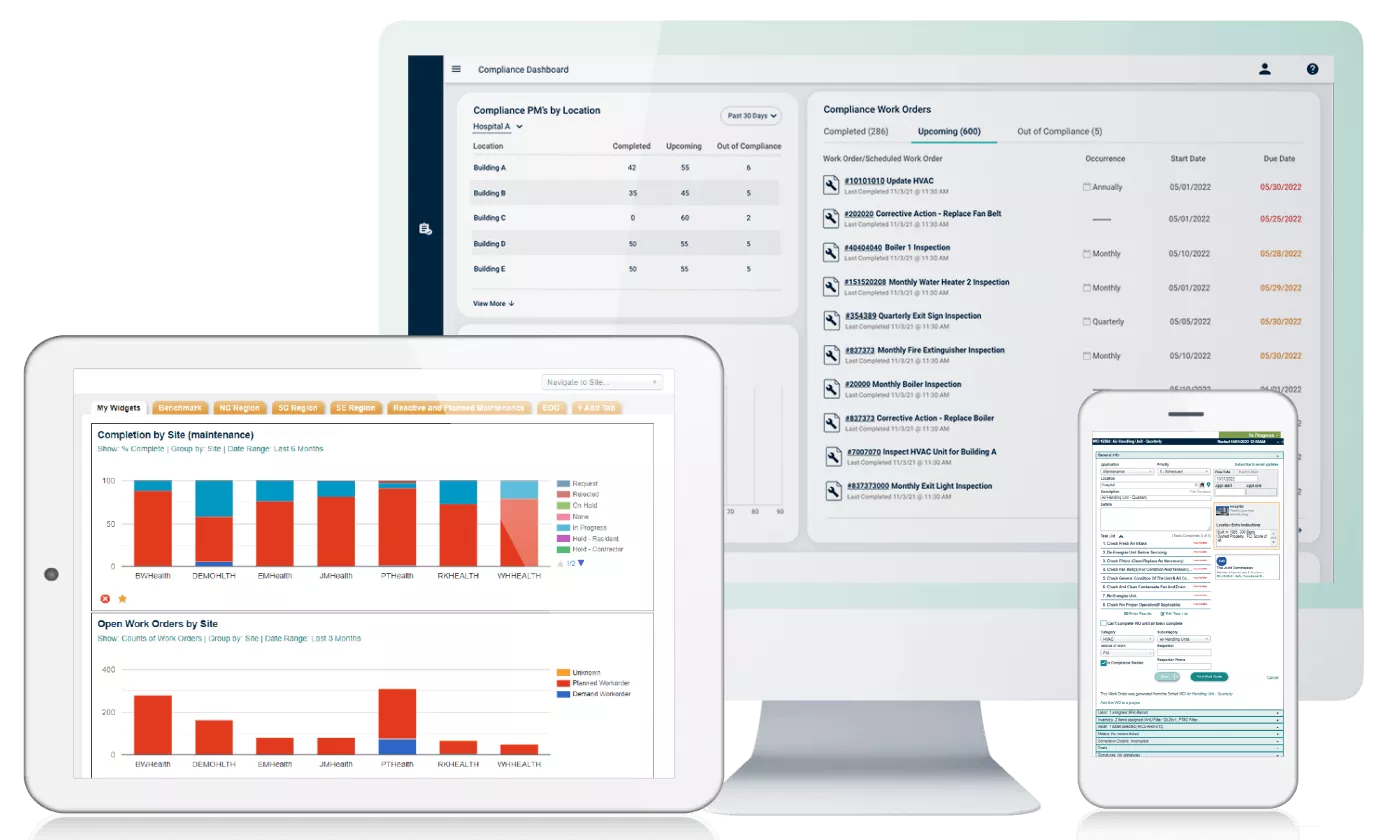

Establish asset hierarchies, track maintenance history on assets and prioritize planned work.Generate work orders and submit work request via online portal. Develop PM schedule and track inspections of the assets.

Our world-class strategic asset management, asset health, and capital planning solution provides strategic insight into facilities, assets, and resources that help determine where to focus limited funding.

Optimize resources and save time by removing the need to inspect assets physically with real-time asset conditions through sensor data. Operational parameters like temperature, pressure, and humidity are reported in real-time by Smart Assets sensor devices connected to the assets.

Ready to see how Brightly can simplify your asset management?

Or want to ask a question? Contact Us

FAQ

How can a CMMS improve equipment reliability?

A CMMS improves equipment reliability in the distribution industry by enabling proactive and preventive maintenance schedules that reduce the likelihood of unexpected breakdowns. This systematic approach ensures that machinery and equipment are maintained in optimal condition, thereby minimizing downtime and enhancing overall operational efficiency.

Is a CMMS difficult to implement?

Brightly's first-in-class customers service team walks each client through a step-by-step implementation process to ensure a smooth onboarding experience and fully integrated CMMS.

Who uses CMMS software?

CMMS software is used by anyone who manages maintenance — facility managers, operations managers, and asset managers, and more — to manage assets, schedule maintenance, and ensure safety. It is widely employed in industries including manufacturing, education, government, food & beverage, and many more to maintain facilities, infrastructures and assets and manage resources effectively.

Want to uplevel your maintenance and operations?

Let us show you how our industry-leading CMMS can help!